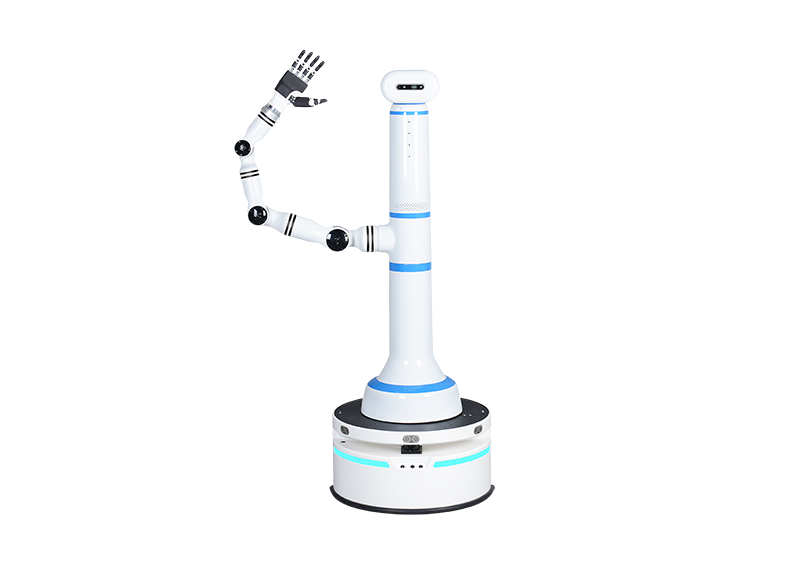

Compared with the traditional compound robot, the compound lifting robot has added a lifting system, further expanding the robot's workspace At the same time, the end of the robotic arm is equipped with execution tools and an open-source 3D visual sensor, ensuring that the robot has higher task accuracy and flexibility.

Advantages

Application Scenarios

Specs

Compound Lifting Robot |

|||

|---|---|---|---|

Model |

RMC-LA | RML-125-1800 | |

Platform size |

Total height 1630mm |

Total height 2430mm |

|

Weight |

About 76kg |

About 88kg |

|

Charging power supply |

Single-phase three-wire 220 V ± 10% 50 Hz |

||

Working voltage |

DC24V | ||

Security protection |

Functions of laser scanning obstacle avoidance, visual obstacle avoidance, force sensors, emergency stop, etc. |

||

External interface |

Network interface, USB interface, HDMI |

||

Working environment |

Temperature -10°C to +40°C, relative humidity ≤ 85% (25°C), altitude<4000m |

||

Voice module |

— | ||

Effective lifting distance |

— | 1.8m | |

Lifting speed |

150mm/s | ||

Main control module |

GPU | 384-core NVIDIA Volta™ GPU with 48 Tensor Cores | |

| CPU | 6-core NVIDIA Carmel ARM®v8.2 64-bit CPU 6MB L2 + 4MB L3 |

||

Memory |

8GB 128-bit LPDDR4x 59.7GB/s |

||

Operating system |

Ubuntu18.04 | ||

Number of network interfaces |

1 | ||

Number of USB3.0 interfaces |

4 | ||

Number of USB2.0 interfaces |

1 | ||

Other interfaces |

GPIOs, I2C, I2S, SPI, UART | ||

Size |

90mm×103mm×35mm | ||

Downloads

Product Manual

-

RealManProduct brochuresV2.1_EN

PDF|5.17MB

Joint Information

-

Tiny Mighty joint module Brochure V1.0_EN

PDF|2.20MB

User Manual

-

RMC-HC-01 Healthcare Robot User Manual V1.0

pdf|1.78M

-

RealMan Robotrm_exampleUser Manual V1.0

pdf|392kb

-

RealMan Robotrm_controlUser Manual V1.0

pdf|236kb

-

RealMan Robotic Arm ROS2 User Manual V1.0

pdf|624kb

-

RealMan Robotic Arm rm_moveit2_config User Manual V1.0

pdf|844kb

-

RealMan Robotic Arm rm_gazebo User Manual V1.0

pdf|260kb

-

RealMan Robotic Arm rm_driver Topic Detailed Description (ROS2) V1.0

pdf|312kb

-

RealMan Robot rm_ros_interface User Manual V1.0

pdf|184kb

-

RealMan Robot rm_driver User Manual V1.0

pdf|324kb

-

RealMan Robot rm_description User Manual V1.0

pdf|344kb

Control Software

-

RML63 V6.1.4

ZIP|51.4MB

-

RM75 V6.1.4

ZIP|48.5MB

-

RM65 V6.1.4

ZIP|49MB

3D Model

-

ECO65-B

STP|5.23MB

-

ECO65-6F

STEP|11.1MB

-

RM65-B

STEP|9.61MB

-

RM65-ZF

STEP|10.0MB

-

RM65-6F

STEP|10.0MB

-

RM75-B

STEP|9.61MB

-

RM75-ZF

STEP|10.0MB

-

RM75-6F

STEP|10.0MB

-

RML63-B

STEP|5.58MB

-

RML63-ZF

STEP|6.00MB

Dimensional Drawing

-

ECO65 dimension

PDF|36.5KB

-

ECO65 installation drawing

PDF|22.6KB

-

End Effector Installation Dimensional Drawing

PDF|28.4KB

-

Installation Dimensional Drawing of RML63 Series Robot Arm Base

PDF|22.5KB

-

RML63 dimension

PDF|27.5KB

-

Installation Dimensional Drawing of RM65, RM75 Series Robot Arm Base

PDF|21.3KB

-

RM65 dimension

PDF|73.9KB

-

RM75 dimension

PDF|76.9KB

Development Protocol

-

RealMan 6-Dof Robot JSON Protocol-V3.1

PDF|1.01MB

SDK

-

RealMan Robot Interface Function Description V3.1

PDF|805KB

ROS

-

ROS1

zip|12.34MB

-

RM65系列URDF文件

zip|8.00kb

-

ROS2

zip|2.77MB