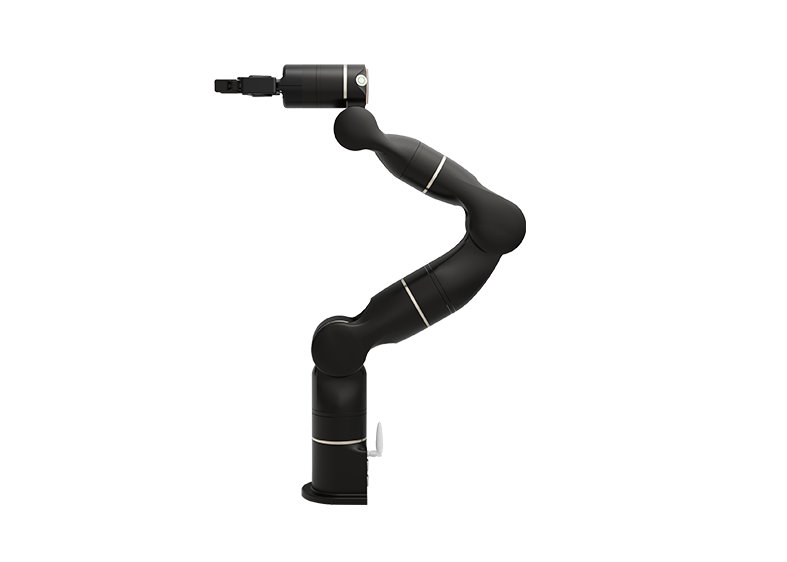

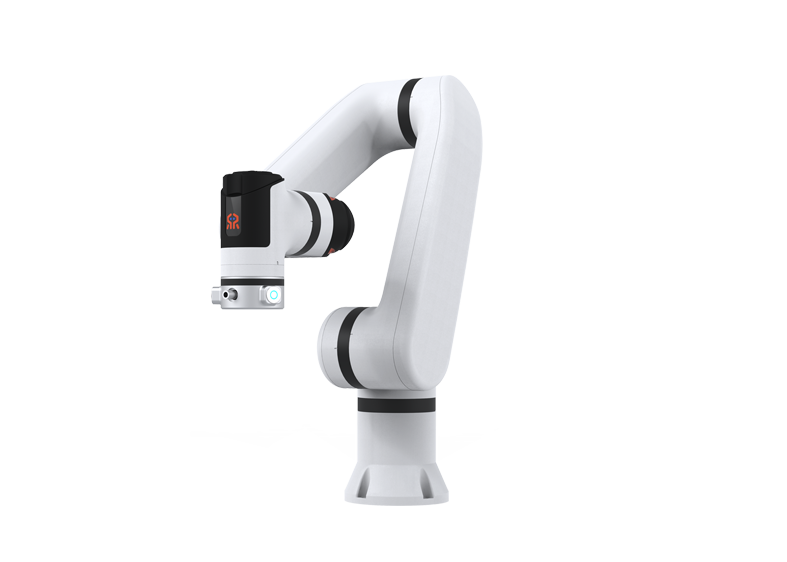

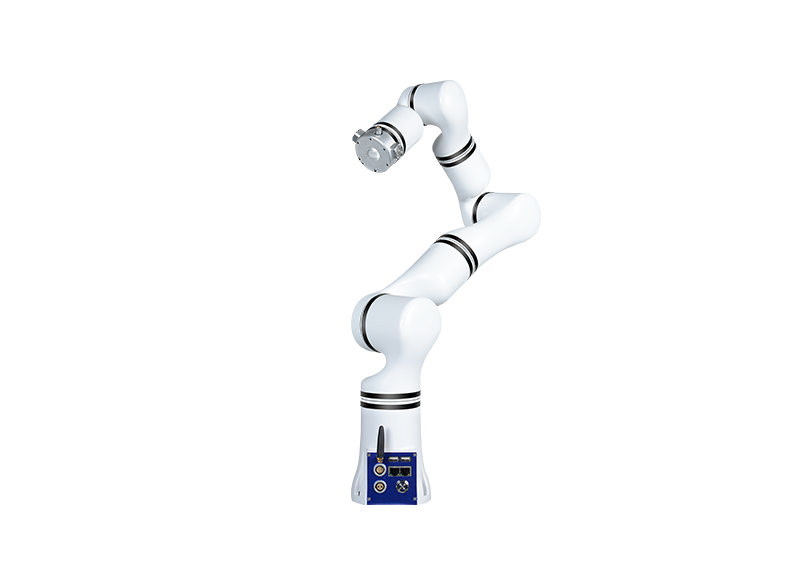

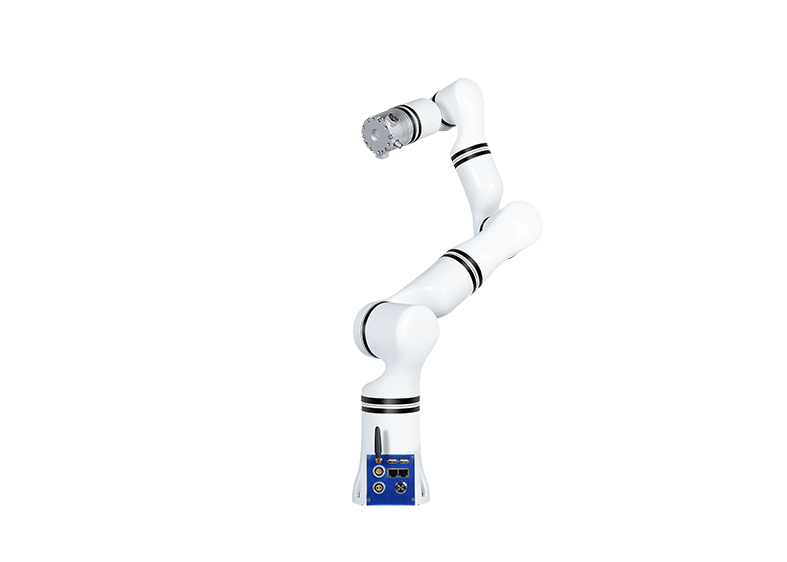

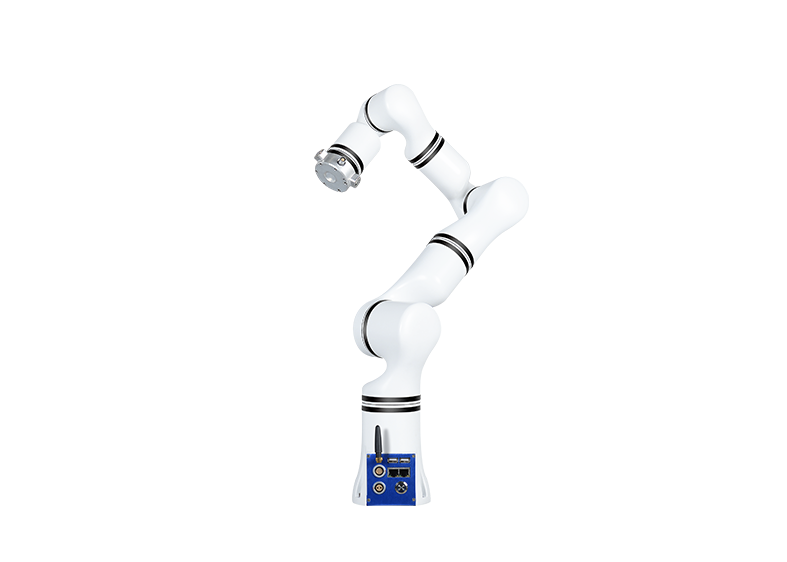

The RML63-B, a basic version of the 6-dof long arm span robotic arm, is self-developed and produced by RealMan. The controller is integrated at the bottom of the robotic arm, lightweight and flexible. The modular joint design of the robotic arm enables sufficient workspace, meeting the requirements of more complex application scenarios. Maximum power consumption ≤200W, comprehensive power consumption ≤100W.

Advantages

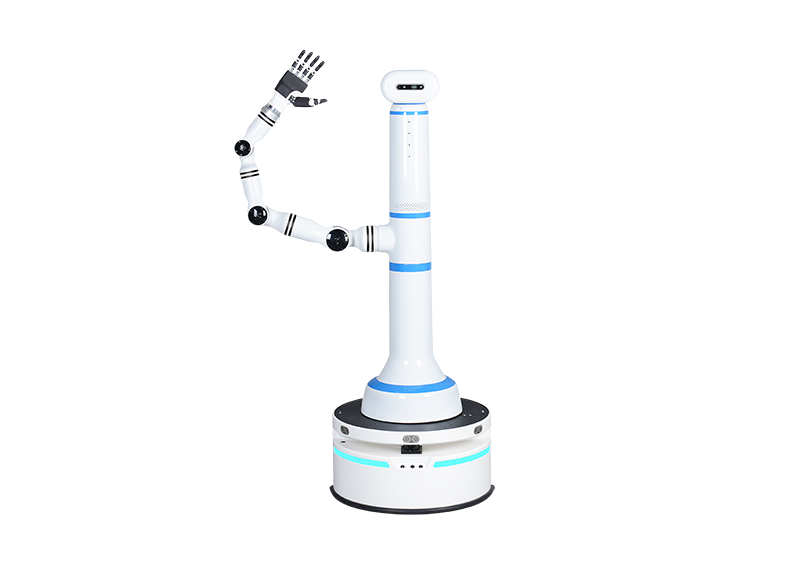

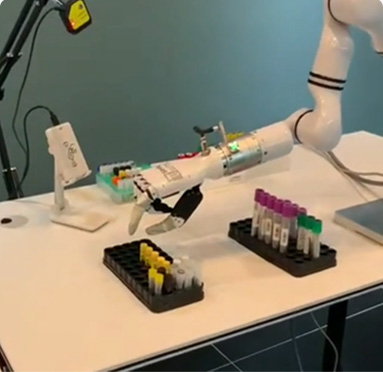

Application Scenarios

Downloads

Product Manual

RealManProduct brochuresV2.1_EN

PDF|5.17MB

Joint Information

Tiny Mighty joint module Brochure V1.0_EN

PDF|2.20MB

User Manual

RMC-HC-01 Healthcare Robot User Manual V1.0

pdf|1.78M

RealMan Robotrm_exampleUser Manual V1.0

pdf|392kb

RealMan Robotrm_controlUser Manual V1.0

pdf|236kb

RealMan Robotic Arm ROS2 User Manual V1.0

pdf|624kb

RealMan Robotic Arm rm_moveit2_config User Manual V1.0

pdf|844kb

RealMan Robotic Arm rm_gazebo User Manual V1.0

pdf|260kb

RealMan Robotic Arm rm_driver Topic Detailed Description (ROS2) V1.0

pdf|312kb

RealMan Robot rm_ros_interface User Manual V1.0

pdf|184kb

RealMan Robot rm_driver User Manual V1.0

pdf|324kb

RealMan Robot rm_description User Manual V1.0

pdf|344kb

Control Software

RML63 V6.1.4

ZIP|51.4MB

RM75 V6.1.4

ZIP|48.5MB

RM65 V6.1.4

ZIP|49MB

3D Model

ECO65-B

STP|5.23MB

ECO65-6F

STEP|11.1MB

RM65-B

STEP|9.61MB

RM65-ZF

STEP|10.0MB

RM65-6F

STEP|10.0MB

RM75-B

STEP|9.61MB

RM75-ZF

STEP|10.0MB

RM75-6F

STEP|10.0MB

RML63-B

STEP|5.58MB

RML63-ZF

STEP|6.00MB

Dimensional Drawing

ECO65 dimension

PDF|36.5KB

ECO65 installation drawing

PDF|22.6KB

End Effector Installation Dimensional Drawing

PDF|28.4KB

Installation Dimensional Drawing of RML63 Series Robot Arm Base

PDF|22.5KB

RML63 dimension

PDF|27.5KB

Installation Dimensional Drawing of RM65, RM75 Series Robot Arm Base

PDF|21.3KB

RM65 dimension

PDF|73.9KB

RM75 dimension

PDF|76.9KB

Development Protocol

RealMan 6-Dof Robot JSON Protocol-V3.1

PDF|1.01MB

SDK

RealMan Robot Interface Function Description V3.1

PDF|805KB

ROS

ROS1

zip|12.34MB

RM65系列URDF文件

zip|8.00kb

ROS2

zip|2.77MB