-

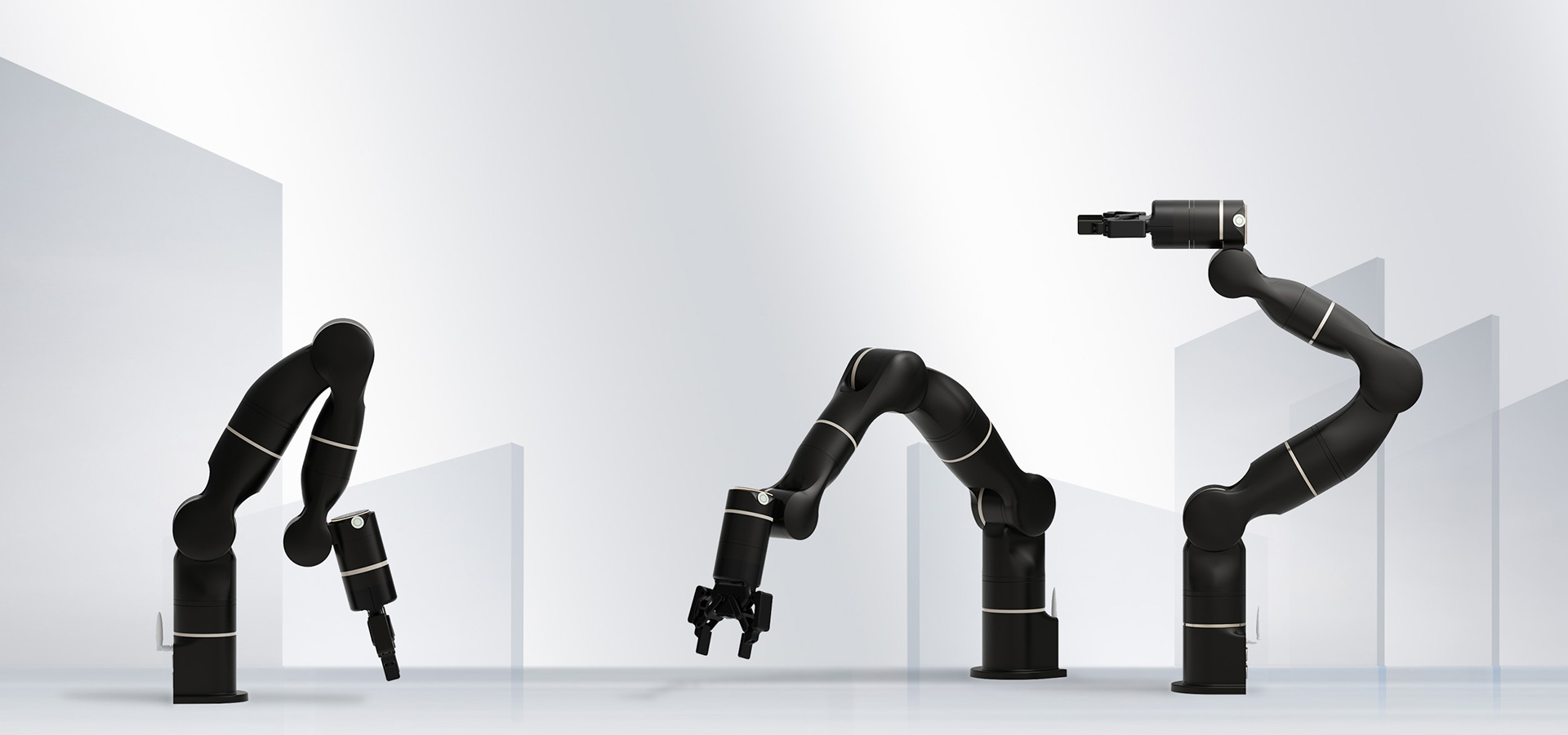

RM Series

Ultra-lightweight Humanoid Robotic Arm

RML Series

Ultra-lightweight Lengthening Robotic Arm

ECO Series

Ultra-lightweight Cost-effective Robotic Arm

GEN Series

Entry Level Affordable Robotic Arm

Compound Robot

Integration, Interactivity and Openness

Accessory

Eco-industrial Chain

Robot integrated actuator

Integration, Interactivity and Openness

Service

RM Series

Weight: 7.2kg Payload: 5kg Range:610cm

RML Series

Weight: 10kg Payload: 3kg Range:900cm

ECO Series

Weight: 7.8kg Payload: 5kg Range:610cm

GEN Series

Weight: 6.6kg Payload: 2kg Range:600cm

Compound Robot

Embodied Intelligent Robot, Created with an RealMan Robotic Arm

Accessory

Our robotic arm operates in an open environment

Robot integrated actuator

Tinier in Size, Mightier in Power

Service

Computer system design

En

En